Running a warehouse is hard.

When you think you have a Labor Overtime Productivity Efficiency Automation Trailer Detention Cost problem...

You actually have a decision overload problem

This problem stops when decisions work… together.

Warehouses now make more decisions per hour than people can manage. Your WMS is imperfect and can actually make the problem worse. When labor, automation, yard, and execution all change at the same time, decisions happen in silos. Firefighting becomes the operating model, hiding margin, driving burnout, and incurring cost no one sees.

Trusted by Industry Leaders

Firefighting Is a Symptom of a Broken Decision System.

Everything changes constantly in the warehouse. Labor Availability is Disrupted. Trailers run late. Automation slows. Priorities change mid-shift.

Without a system orchestrating optimal decisions across these changes, managers are forced to react. Firefighting feels productive, but it’s a sign that decision overload has exceeded what people and disconnected systems can manage.

Download Whitepaper

The High Cost of Labor Firefighting and Systemic Attrition

Your WMS executes work. It doesn’t coordinate decisions.

Your WMS maintains data and executes tasks.

More Warehouse Management System configurations do not orchestrate warehouse decisions. The WMS was built to execute tasks, not coordinate the operation.

You do not need to replace your WMS. You need a decision layer on top that makes all warehouse decisions work together as conditions change.

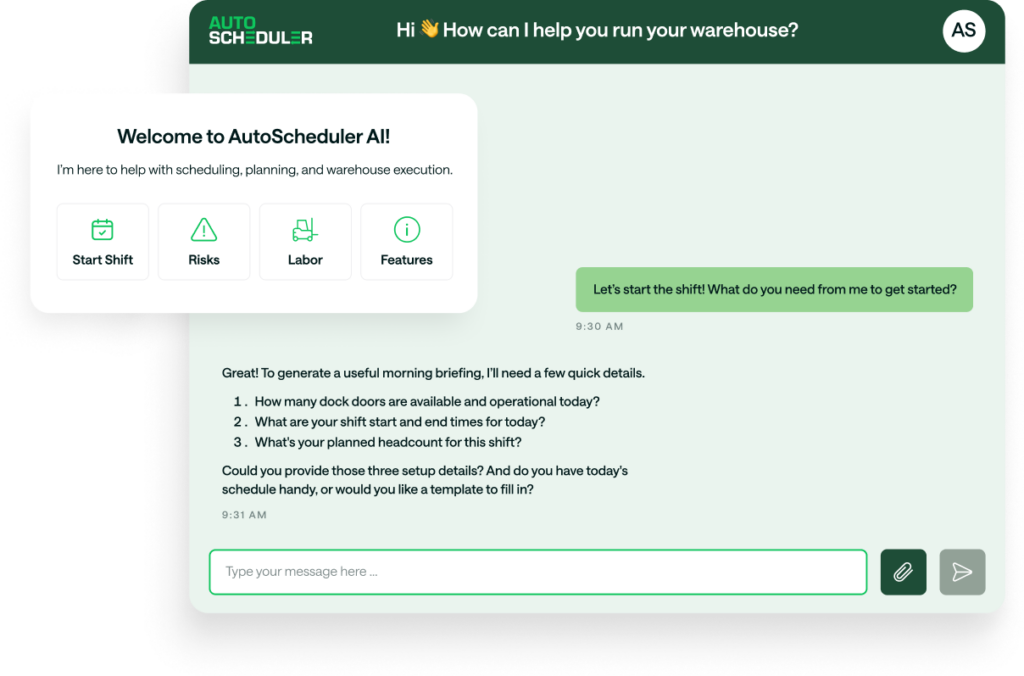

Meet the Warehouse Decision Agent

AutoScheduler is the Decision Agent that orchestrates your warehouse by providing the optimal decisions for labor, yard, execution, and automation together on top of your existing WMS.

Decision overload shows up everywhere

Why Warehouse Labor Plans Fail

Warehouse labor planning, near and long-term, is a major challenge due to work volatility, transportation variability, and constant disruptions. When sites struggle, turnover rises, overtime spikes, and supervisors get pulled into firefighting. Better decision making around labor planning drives more efficiency, less chaos, lower cost, and improved service.

Why Warehouse Automation Sits Idle

Robotic workflows require smooth interchanges at ingress and egress. When flow breaks down, high-cost equipment sits idle or queues build and waste labor. The firefighting to keep things moving may feel productive, but it destroys warehouse automation ROI. Optimized decisions improve automation utilization, robotics performance, and throughput per hour while reducing downtime.

Why Dock Delays and Trailer Detention Never Go Away

How decisions are made in the building is the greatest driver of trailer and driver detention. Missed warehouse opportunities become delays, and delays become detention costs. Optimized dock scheduling and labor flow in the building increase dock door utilization and improve trailer turn time.

Why Warehouse Execution Falls Apart During the Shift

Warehouse execution struggles when orders stack unpredictably and conditions around labor, automation, and transportation change. Productivity dips as urgency rises to fix issues, and actual throughput and service levels collapse. The result is lower orders per hour and growing execution variability.

Built for complex warehouse operations

What Our Customers Are Saying

What happens when decisions work together

+35%

increase in product flow

“The optimized plan now defines: Who does the work, what tasks they perform, when it starts and ends, and where it happens—creating order from chaos.”

Warehouse Orchestration Sr Manager

Fortune 100 F&B Company

9-14%

average productivity gains per facility

“It doesn’t matter who is leading the team… You could have a brand-new employee working on an off-shift and have the same information and the same decision-making capability as a 15-20-year employee.”

Warehouse Orchestration Sr Manager

Fortune 100 F&B Company

96%

savings in workforce planning time

P&G’s Lima success demonstrates how AutoScheduler solves the unique complexities of plant-attached warehouses—dynamic production schedules, constrained space, and labor variability— turning chaos into flow

PROCTER & GAMBLE

Frequently Asked Questions

When you’re doing novel things in the supply chain industry, we get many of the same questions pretty frequently. We’ve answered some of them here and are happy to talk about any of them in further detail.

What is a Warehouse Decision Agent?

A Warehouse Decision Agent is an AI system that continuously coordinates operational decisions across labor, docks, equipment, and work priorities in real time.

Unlike traditional software that executes pre-set workflows, a decision agent senses what is happening on the floor, recalculates the best plan, and orchestrates actions as conditions change. It turns fragmented data into coordinated decisions so the warehouse runs as one system instead of disconnected parts.

What is Agentic AI in warehouse operations?

Agentic AI refers to AI systems that don’t just analyze or recommend, but actively make decisions and take action within defined goals and constraints.

In a warehouse, Agentic AI monitors operations, detects disruptions, evaluates tradeoffs (service, cost, throughput, labor), and continuously adjusts the plan. Instead of humans stitching together systems and rules, the AI acts as a decision layer that keeps operations aligned in real time.

How is a Warehouse Decision Agent different from a WMS?

A WMS manages transactions and executes workflows. A Warehouse Decision Agent decides how work should be prioritized and coordinated across the operation.

The WMS is great at tracking inventory and executing tasks. The Decision Agent sits above it, orchestrating labor, docks, waves, and priorities across systems to achieve business outcomes like higher service levels, better throughput, and lower overtime.

Why isn’t a WMS enough to run a modern warehouse?

ecause a WMS was designed to execute plans, not continuously re-plan and coordinate decisions across the operation.

Modern warehouses face constant disruptions: labor shortages, late trucks, rush orders, automation constraints, and shifting priorities. A WMS doesn’t resolve these tradeoffs. That gap forces managers into manual firefighting. A WarDecision Agent fills that gap by continuously optimizing and coordinating decisions in real time.

What does “decision orchestration” mean in a warehouse?

Decision orchestration means coordinating thousands of daily operational decisions so they work toward the same business goals instead of conflicting with each other.

Instead of each system or team optimizing locally, orchestration aligns labor, docks, equipment, and priorities around a single, continuously updated plan. The result is fewer bottlenecks, less rework, and better overall performance.

Ready to Run Smarter?

Every warehouse is unique. Let us help you solve your biggest challenges with solutions tailored to your operations.