ADVANCED WAREHOUSE PLANNING AND OPTIMIZATION

AutoPilot dynamically orchestrates all activities on top of your existing WMS – in real-time. As a result, our Gartner-lauded solution can optimize and drive value without IT or management headaches.

Advanced Warehouse Planning drives higher degrees of warehouse labor and equipment utilization, reducing labor costs and increasing order fulfillment rates by optimizing work allocation while considering warehouse constraints.

Put your warehouse planning on AutoPilot with AutoScheduler’s solution.

With more supply chain challenges than ever, AutoPilot combines data from numerous systems into a single operational plan for warehouses and distribution centers. It takes disparate data, identifies bottlenecks, and prescriptively creates plans to orchestrate campus operations for optimized efficiency.

Request an Assessment

THE PROBLEMS WE SOLVE

Eliminating chaos in your warehouse operations better and faster. Find out how!

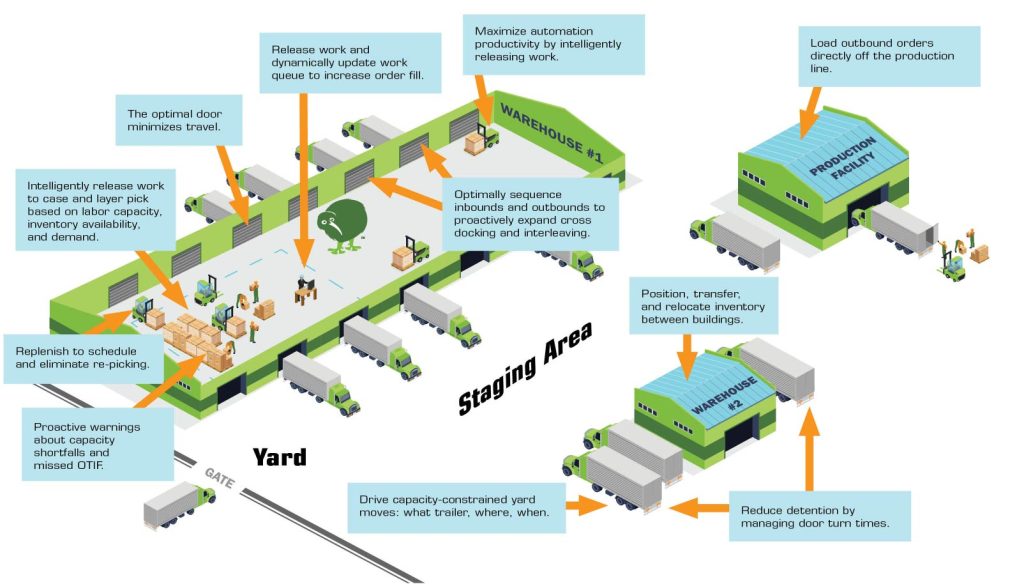

Maximize automation productivity by intelligently releasing work.

Optimally sequence inbounds and outbounds to proactively expand cross docking and interleaving.

Release work and dynamically update work queue to increase order fill.

The optimal door minimizes travel.

Intelligently release work to case and layer pick based on labor capacity, inventory availability, and demand.

Load outbound orders directly off the production line.

Position, transfer, and relocate inventory between buildings.

Reduce detention by managing door turn times.

Drive capacity-constrained yard moves: what trailer, where, when.

- Increase Order Fill

- Minimize Travel

- Release Work

- Intelligently

- Eliminate Re-picks

- Capacity Warnings

- Yard Moves

- Door Turns

- Intra-Campus

- Transfers

- Cross-Docking

- Automation

- Productivity

- Outbound Production

AUTOPILOT

AutoPilot is a warehouse resource planning and optimization platform that dynamically orchestrates all activities on top of your existing WMS in real-time. Our Gartner-lauded solution can optimize and drive value without IT or management headaches.

SHUTTLE MANAGMENT

Minimize inventory moves across your campus of buildings by automating the planning of transfers and intelligently relocating shipments and receipts.

MAKE-N-SHIP

Tie customer and site orders directly to a dynamic production schedule, specifying how many trailers you need per lane, days ahead of time. This optimizes trailer usage around your production campus in real-time.

UNDERSTANDING THE VALUE OF

ADVANCED WAREHOUSE PLANNING

- Increase Controllable Fill Rate - More products mean more revenue.

- Reduce Planning Time - Algorithmically automate wave (or waveless) planning for your team to approve.

- Increase Capacity - Get more per person, thanks to an optimized schedule.

- Reduce overtime

- Reduce headcount - Decrease Detention Time - Turns doors more quickly and directs work in the yard.

0.5% – 2%

5% – 15%

30% – 50%

- Increase Controllable Fill Rate - More product means more revenue 0.5% - 2%

- Reduce planning time - algorithmically automate wave (or waveless) planning, and your team just needs to approve 40% - 75%

- Increase Capacity - get more per person thanks to an optimized schedule

- Reduce overtime

- Reduce headcount

5% - 15% - Decrease detention time - Turns doors more quickly and direct work in the yard

30% - 50%

0.5% – 2%

40% – 75%

5% – 15%

30% – 50%

UNDERSTANDING THE VALUE OF

ADVANCED WAREHOUSE PLANNING

WORK WITH US

Want to understand better how to smooth operations in your warehouse? Schedule a complimentary assessment today to prove the ROI needed to build your business case. No strings attached!

– Gartner Magic Quadrant for Warehouse Management Systems Simon Tunstall, Dwight Klappich, 6 May 2020