Knowledge at Your Fingertips

Explore our collection of valuable resources designed to help you optimize warehouse operations and get the most out of AutoScheduler.

Never Miss An Update

Get smarter strategies delivered straight to your inbox.

By submitting this form, you agree to be contacted by AutoScheduler – in accordance with AutoScheduler’s Terms of Use and Privacy Policy.

In the News

Press

Case Studies

From optimizing labor to improving throughput, explore how AutoScheduler delivers measurable results and drives warehouse excellence.

Frequently Asked Questions

When you’re doing novel things in the supply chain industry, we get many of the same questions pretty frequently. We’ve answered some of them here and are happy to talk about any of them in further detail.

How do I know if AutoScheduler will be useful for my organization?

We can help you with that. Before deciding to dive in and implement the full AutoScheduler solution, we can do a short-term return on investment analysis that only takes a few weeks. This will help you to understand how much can be saved by working with us.

You say you use machine learning. What does that mean?

AutoScheduler is designed to optimize all operations, but the problem is, every warehouse is different. AutoScheduler uses machine learning to predict better what is likely to happen inside of a facility. For example, if Steve is case picking and it’s 5:30 AM, and there is a backlog of 12 orders up next, each layer will take 8 minutes instead of the expected 10 minutes.

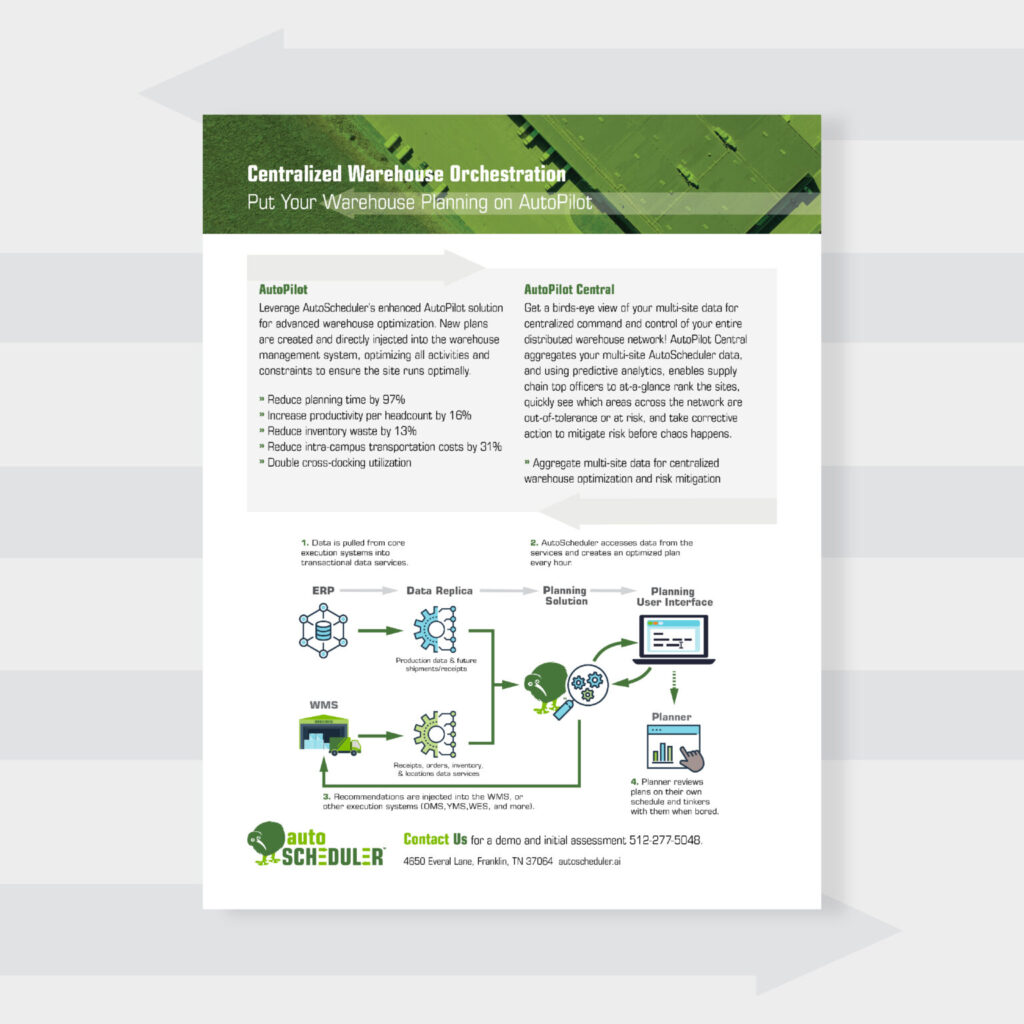

What are some of the warehouse activities that AutoScheduler orchestrates?

The AutoScheduler solution is designed to focus on all of your warehouse’s critical activities, so things like dock scheduling, loading, unloading, case picking, and the creation of transfer orders are all optimized. In the end, we want to make sure that everything gets where it needs to when it needs to be there.

Are other clients using the AutoScheduler solution today?

The AutoScheduler solution was built and developed for one of the world’s largest consumer goods companies, Procter & Gamble. P&G has consistently lived in the “Master’s” category of the Gartner Top 25 for their supply chain execution. Since we received the green light to bring AutoScheduler to market, we have brought on several other of the world’s largest companies as customers. See our customer page for more details.

How much work will my IT team have to do when we integrate AutoScheduler?

For the limited analysis, very little IT input is required. We just need some data. For a full-scale WMS and ERP integration, we’ll work with your IT team on getting access to about 300 data fields from each system. Don’t worry, though. We’re experts, and this process is pretty painless. If we want to get really fancy, we’ll also want the capability to write back to your WMS so that it can remain the single source of truth.

Warehouse Game

Are you up for the challenge?

Do you know how to run and optimize a distribution center? Show us your skills! We have a warehouse game that gives you the information you need to manage a warehouse and achieve the objectives we’ve identified.

Drive Operational Excellence Across Your Network

Every warehouse faces its own set of challenges. Let AutoScheduler provide tailored solutions that streamline your operations and drive efficiency.