Dock Optimization

Dock operations can be challenging with limited space, personnel, and inventory. AutoScheduler optimizes the flow, maximizing efficiency and minimizing delays.

How AutoScheduler Optimizes Docks

AutoScheduler takes dock management to the next level by blending real-time adaptability, predictive analytics, and end-to-end visibility. The result? Shorter travel distances, fewer delays, and a smoother flow that drives efficiency.

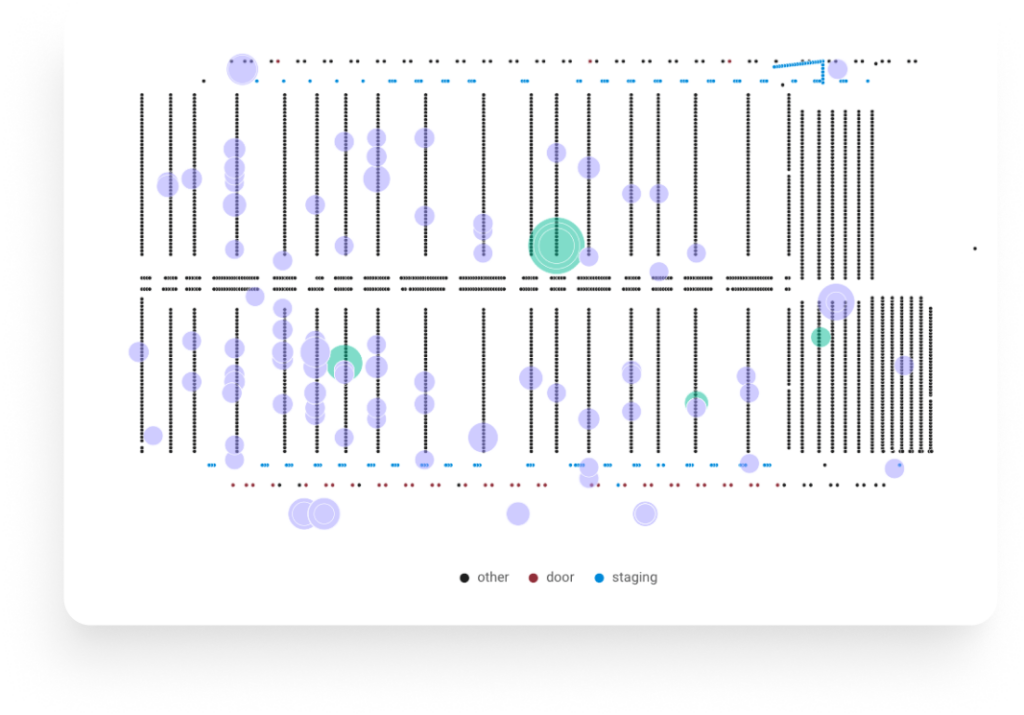

Minimize Travel Through Dynamic Dock Allocation

Stop sending workers on long hauls across the warehouse. AutoScheduler’s dynamic dock assignments leverage predictive analytics to choose the optimal docks and timing, cutting down on unnecessary travel. With integrated, multi-point decision-making and a full view of your operation, AutoScheduler places the right product at the right dock every time, minimizing forklift runs and inefficient routes.

Adaptability in Real-Time

When conditions shift—unexpected delays, early arrivals, sudden priority changes—AutoScheduler responds in real-time. It recalibrates dock assignments and load sequences, keeping operations on track without missing a beat.

Intelligent Prioritization

Work smarter, not harder. By analyzing truck schedules, demand forecasts, and warehouse constraints, AutoScheduler identifies the most impactful actions first. The system pinpoints which products to move when and where, ensuring resources are deployed for maximum effect.

Keep Things Moving by Reducing Congestion

No more traffic jams at the dock. AutoScheduler spreads out workloads across zones and doors, balancing activities to keep equipment and automation systems running smoothly.

Customer Results

See the Real-World Impact of AutoScheduler in Action

35%

Improvement in product flow at automated sites

50%

Reduction in short ships

12%

Increase in productivity

33%

Shorter detention and dwell times

Benefits of Dock Optimization with AutoScheduler

AutoScheduler’s dock optimization features offer significant improvements to your operations:

AutoScheduler keeps your docks running at full speed by assigning the right products to the right docks in real-time. This means less waiting and more moving, so trucks are loaded and unloaded faster, keeping everything on schedule and boosting throughput.

Make the most of your dock space with smarter workload balancing. AutoScheduler prevents congestion by spreading activity across doors and zones, ensuring every inch of your dock is working efficiently, even during peak times.

By reducing delays and shortening travel distances inside the warehouse, AutoScheduler helps lower your transportation spend. Faster truck turnarounds keep carriers happy and your costs in check.

Seamless dock operations mean smoother workflows throughout your facility. AutoScheduler dynamically adjusts to real-time conditions, keeping goods moving in and out effortlessly without bottlenecks or interruptions.

Stay on top of dock performance with clear, actionable insights. AutoScheduler tracks key metrics like turnaround times, dock utilization, and on-time performance, giving you the tools to keep improving operations.

Say goodbye to costly delays. With intelligent prioritization, AutoScheduler keeps trucks moving quickly, cutting down on detention fees and ensuring your docks are always ready.

When your docks run like clockwork, goods leave on time, every time. AutoScheduler helps you maintain reliability and build stronger relationships with carriers and customers by ensuring on-time delivery rates stay high.

Faster Turnaround Times

Speed up the flow of goods in and out of your docks.

AutoScheduler keeps your docks running at full speed by assigning the right products to the right docks in real-time. This means less waiting and more moving, so trucks are loaded and unloaded faster, keeping everything on schedule and boosting throughput.

Better Dock Utilization

Make every corner of your dock space count.

Make the most of your dock space with smarter workload balancing. AutoScheduler prevents congestion by spreading activity across doors and zones, ensuring every inch of your dock is working efficiently, even during peak times.

Lower Transportation Costs

Keep transportation budgets in check.

By reducing delays and shortening travel distances inside the warehouse, AutoScheduler helps lower your transportation spend. Faster truck turnarounds keep carriers happy and your costs in check.

Improved Flow of Goods

Seamless movement in and out of your facility.

Seamless dock operations mean smoother workflows throughout your facility. AutoScheduler dynamically adjusts to real-time conditions, keeping goods moving in and out effortlessly without bottlenecks or interruptions.

KPI Tracking & Reporting

See the data, make better decisions.

Stay on top of dock performance with clear, actionable insights. AutoScheduler tracks key metrics like turnaround times, dock utilization, and on-time performance, giving you the tools to keep improving operations.

Reduced Detention Costs

Avoid unnecessary fees and delays.

Say goodbye to costly delays. With intelligent prioritization, AutoScheduler keeps trucks moving quickly, cutting down on detention fees and ensuring your docks are always ready.

Increased On-Time Delivery

Keep your promises to carriers and customers.

When your docks run like clockwork, goods leave on time, every time. AutoScheduler helps you maintain reliability and build stronger relationships with carriers and customers by ensuring on-time delivery rates stay high.

Testimonials

Hear what our customers are saying

“Optimizing dock utilization and unload time improves our crewing because travel times are reduced and hot shipments are always worked in appropriate priority.”

– First Shift Warehouse Supervisor, Enterprise CPG

Say Goodbye to Dock Delays

AutoScheduler intelligently assigns trailers to the right doors, minimizing delays and maximizing dock space. Discover the difference.